In an era where technology is rapidly transforming industries, understanding advanced manufacturing techniques and the integration of new technologies is crucial for tech professionals. This blog post delves into the essential technical concepts, educational opportunities, and industry trends that can shape your career in manufacturing and technology. Here’s what you can expect to learn:

- Key advancements in manufacturing technologies.

- Practical applications and use cases for tech professionals.

- Recommended learning paths and certifications to enhance your skills.

- Insights into industry trends and their implications for career development.

Technical Background and Context

The manufacturing sector is undergoing a significant transformation driven by advanced technologies. With the rise of Industry 4.0, businesses are increasingly investing in innovative techniques that enhance productivity and performance. Key advancements include:

- Advanced Manufacturing Technologies: Techniques such as additive manufacturing (3D printing), robotics, and automation are streamlining processes and reducing costs.

- Research and Innovation: Ongoing research initiatives focus on sustainable practices, energy efficiency, and product lifecycle management, which are vital for modern manufacturing ecosystems.

- Internet of Things (IoT): The integration of IoT in manufacturing allows for real-time data collection and analysis, facilitating predictive maintenance and operational efficiency.

Practical Applications and Use Cases

Understanding how these technologies are applied in real-world scenarios can enhance your skills and knowledge. Here are a few examples:

📚 Recommended Digital Learning Resources

Take your skills to the next level with these curated digital products:

Academic Calculators Bundle: GPA, Scientific, Fraction & More

Academic Calculators Bundle: GPA, Scientific, Fraction & More

ACT Test (American College Testing) Prep Flashcards Bundle: Vocabulary, Math, Grammar, and Science

Java Essentials: 100 Powerful Topics for Fast-Track Learning | PDF Download

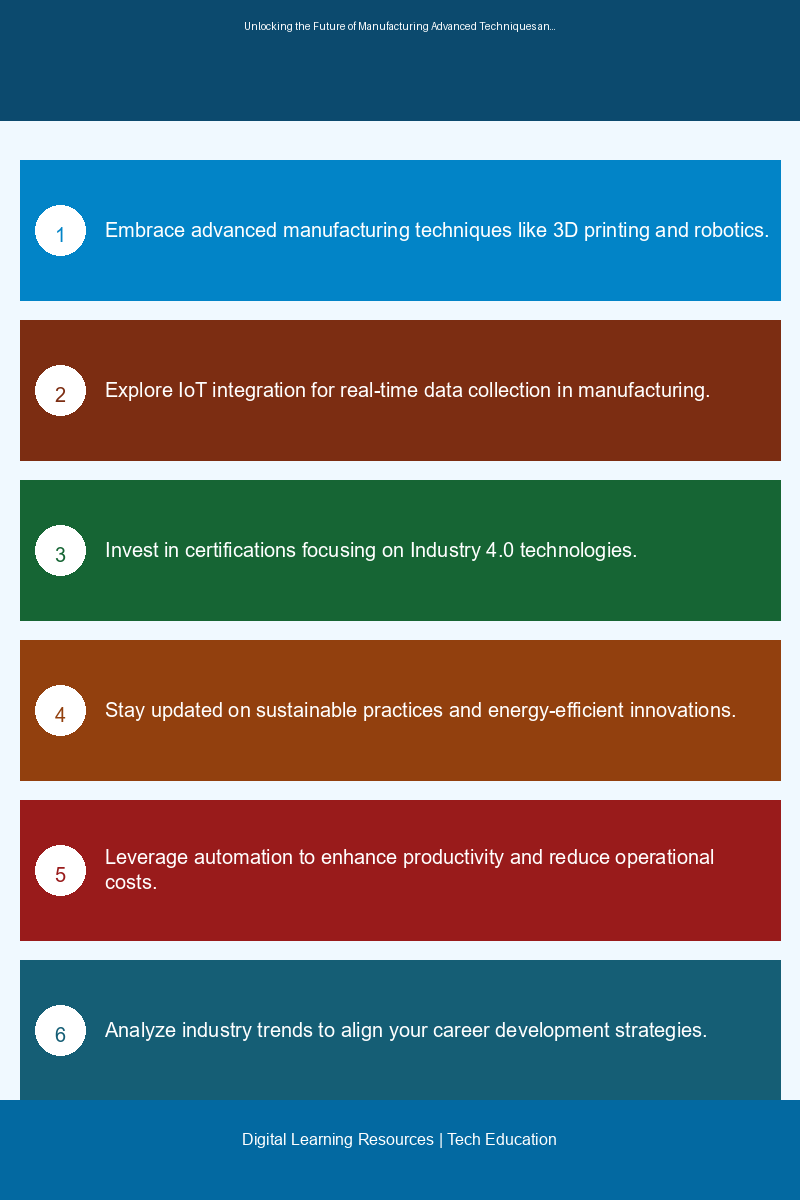

📊 Key Learning Points Infographic

Visual summary of key concepts and actionable insights

Leonardo.Ai API Mastery: Python Automation Guide (PDF + Code + HTML

Leonardo.Ai API Mastery: Python Automation Guide (PDF + Code + HTML

100 Python Projects eBook: Learn Coding (PDF Download)

JavaScript for Web Development eBook | Learn to Build Interactive Websites

HSPT Vocabulary Flashcards: 1300+ Printable Study Cards + ANKI (PDF)

HSPT Vocabulary Flashcards: 1300+ Printable Study Cards + ANKI (PDF)

- Smart Factories: By leveraging IoT and AI, smart factories optimize production lines, reduce downtime, and enhance product quality through data-driven decision-making.

- Supply Chain Optimization: Technologies such as blockchain and IoT improve transparency and traceability in supply chains, leading to better inventory management and reduced waste.

- Energy Management: Advanced research initiatives in energy efficiency technologies help manufacturing plants reduce their carbon footprint and lower operational costs.

Learning Path Recommendations

To thrive in the evolving manufacturing landscape, consider the following learning paths:

- Programming and Software Development: Enhance your skills in programming languages such as Python, C++, or Java, which are essential for developing automation solutions.

- IoT and Data Analytics: Explore courses on IoT frameworks, data analytics, and machine learning to understand how to leverage data for operational improvements.

- Certifications: Consider certifications such as Certified Manufacturing Engineer (CMfgE) or Certified Automation Professional (CAP) to validate your expertise and enhance your credibility in the manufacturing sector.

Industry Impact and Career Implications

The integration of advanced technologies is reshaping job roles within the manufacturing industry. Professionals who possess a blend of technical skills and innovative thinking are in high demand. Key implications for your career include:

- Increased Job Opportunities: As companies adopt new technologies, the demand for skilled professionals in areas like IoT, automation, and data analysis is surging.

- Cross-Disciplinary Roles: The merging of technology and manufacturing creates opportunities for roles that require a blend of engineering, business, and research skills.

- Continuous Learning: Staying updated with industry trends and technologies is crucial for career advancement. Engaging in continuous education will keep your skills relevant.

Implementation Tips and Best Practices

As you navigate the integration of advanced technologies in your work, consider these practical implementation tips:

- Start Small: Begin by implementing pilot projects to test new technologies before scaling them across your organization.

- Collaborate Across Departments: Foster collaboration between IT, engineering, and production teams to ensure seamless integration of new solutions.

- Invest in Training: Provide ongoing training for your team to familiarize them with new tools and methods, ensuring a smooth transition.

Future Trends and Skill Requirements

Looking ahead, several trends are likely to shape the manufacturing sector:

- AI and Machine Learning: The increasing use of AI for predictive analytics and process optimization will require professionals skilled in data science and machine learning.

- Sustainable Manufacturing: As sustainability becomes a priority, knowledge of green technologies and practices will be essential for future manufacturing roles.

- Cybersecurity: With the rise of connected devices, understanding cybersecurity measures in manufacturing systems will be crucial to protect sensitive data.

Conclusion with Actionable Next Steps

The future of manufacturing is bright, driven by technological innovation and a focus on efficiency. To position yourself for success in this evolving landscape, take the following actionable steps:

- Identify relevant courses or certifications that align with your career goals.

- Engage in hands-on projects to apply what you’ve learned in real-world situations.

- Network with industry professionals to stay informed about trends and opportunities.

By staying proactive and adaptable, you can leverage the advancements in manufacturing to propel your career forward in this dynamic field.

Disclaimer: The information in this article has been gathered from various reputed sources in the public domain. While we strive for accuracy, readers are advised to verify information independently and consult with professionals for specific technical implementations.

Ready to advance your tech career? Explore our digital learning resources including programming guides, certification prep materials, and productivity tools designed by industry experts.